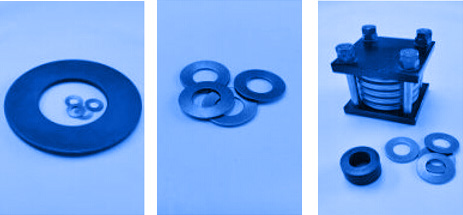

Belleville Disc Springs

elleville disc springs (also known as belleville disc washers) were invented by Julien-Francoise Belleville, who was awarded a patent in 1861 for a spring designed like a cone-shaped ring, capable of absorbing large axial forces with relatively small spring travel. Mubea has proudly manufactured Belleville springs in our Daaden, Germany plant since 1960.

Disc springs can be designed to meet the specific requirements of a variety of applications. These requirements can typically be met with springs from Mubea’s standard product line. Our standard product line includes disc springs designed per the requirements of DIN 2093, our own internal factory standards, as well as other specal sizes. Disc springs from our standard product ine are typically available from stock for immediate delivery.

Disc Spring Theory

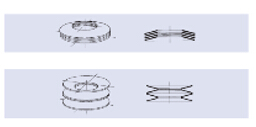

According to the disc spring theory,Belleville springs (also known as Bellevillewashers) are shallow conical ringsthat are subjected to axial loads.Normally, the ring thickness is constant and theapplied load is evenly distributed over the upper inside and lower outside edges. Disc springs are generally manufactured from spring steel and can be subjected to static loads, rarely alternating loads, and dynamic loads. Disc springs can meet the most stringent fatigue life and set loss requirements.

Common Disc Spring Alloys

Copper Beryllium (CuBe)

(CuBe)Cr-Ni-Mo Stainless Steel

Cr-Ni-Mo

Nickel-Beryllium(NiBe)

Inconel

Nimonic

Chromoly Steel

Materials

Belleville Washer Features

DIN 2093

standards High fatigue lifeDifferent assemblies can be designed

to achieve the desired load characteristicsSpecial materials and various surface

coatings availableBetter space utilization when compared

to other spring typesLow creep tendency with the correct

dimensioningHigh load capacity with a small spring

deflection